Footwear is no longer a fashion category. It is a systems problem disguised as style. The market can be tough on brands that only focus on aesthetic shapes but ignore more practical aspects like material behavior under load, sweat, and heat exposure. The customer may be attracted by shape, but customer retention can only be done by maintaining rigorous shoe quality. That means durable materials and production consistency. This is the combination that decides whether a shoe line scales or stays stagnant.

This playbook dissects how the best shoe collection types are built, not decorated. It treats shoes as load-bearing consumer hardware. Because that is what they are.

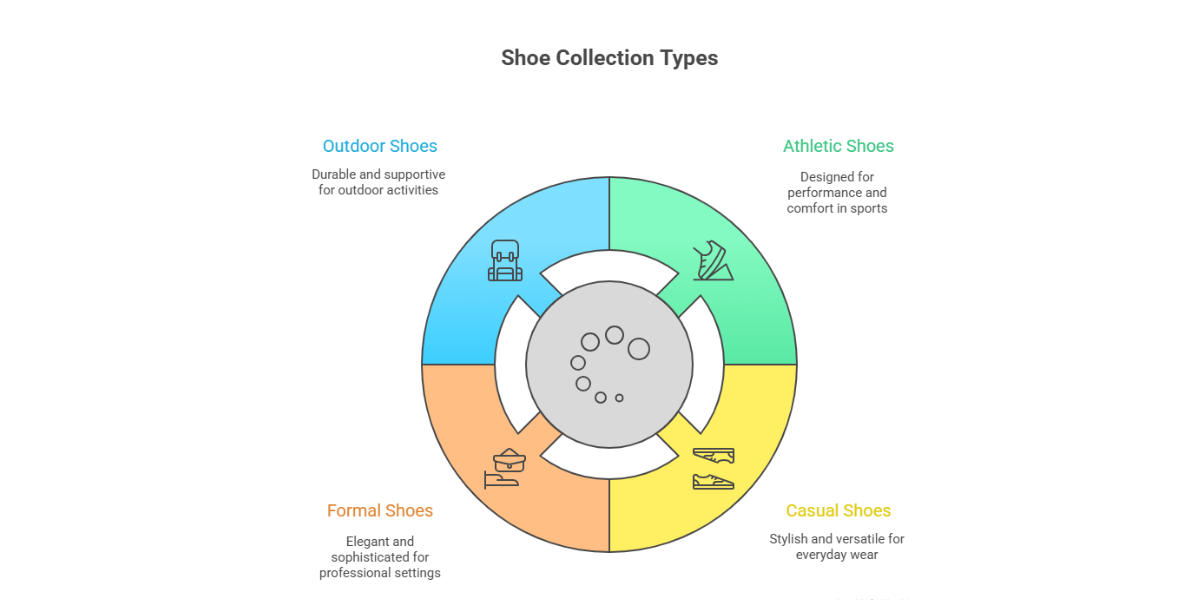

For a shoe manufacturer, each SKU consumes development time. Multiple expenses are incurred like tooling expense, sampling cycles, and working capital. When collections are built without segmentation, they compete with each other, and the result is a mediocre brand. The winning brands do not stock shoes. They maintain separate collections that cater to different customer segments. Performance shoes for athletic users. Lifestyle hybrids for daily wear.

Personalized designs for formal and outdoor categories. Each cluster has its own material philosophy and tolerance thresholds. This segmentation establishes a cohesive identity for each customer type. It also makes quality assurance straightforward. The result is repeated sales and returning buyers.

Durability is all about measured performance. Some important parameters are abrasion resistance tested on DIN 53516 drums. Other durability tests include flex-fatigue cycles of running past 30,000 bends without upper cracking and hydrolysis resistance validated through accelerated aging at 70°C and 95 percent humidity.

Synthetic leathers are subjected to different quality tests, such as 50,000 Martindale rubs without surface peel to see of, they can survive that. Other tests that prove synthetic materials' hardiness include tensile integrity after wash abrasion (crucial for engineered meshes) and UV exposure. For EVA midsoles, compression set testing is done and the rebound rate must be above 60% Ignore these metrics and the shoe may look perfect in a showroom, then unravel in the customer’s living room.

Comfort is not determined by padding thickness, rather it is more related with the pressure points of the sole. The insole’s shore hardness must match load zones. Heel counters need calibrated stiffness, too soft and the ankle collapses, too rigid and blisters erupt.

Shock absorption is another aspect that defines comfort. In shoe design, it is handled through midsole layering. Outsoles with segmented flex grooves aligned to metatarsal joints.

Modern design is no longer just for visual appeal only, it should integrate practical aspects that enhance performance and service life. Some design characteristics that do this include minimalistic shapes which reduce material failure points, and functional detailing such as blind stitching and heat-bonded overlays which remove mechanical weak spots. Good design conceals engineering discipline. Bad design exposes its absence.

Athletic footwear is specially crafted for aggressive and rough usage. It absorbs impact, torque, and sweat. The materials must be breathable but moisture-wicking. The stitching is done to handle intensive forces, which means rubberized toe caps must bond through RF welding or high-frequency heat pressing, not surface gluing.

Agility is vital for any athlete, and athletic shoe design caters to that requirement with midsoles that use supercritical foaming to reduce density while preserving rebound. The solid stitching and hardy materials are not limited to the interior of the shoe. Outsoles incorporate carbon rubber in heel strike zones, and blown rubber at the forefoot for flexibility.

Athletic collections that ignore biomechanics become liabilities. Those that honour them become cult objects.

Casual Lifestyle shoes are everyday wear and are meant for a much longer-term use than sports shoes. They must tackle a variety of surfaces. Office floors. City pavements etc. These shoes must look gentle but behave ruthlessly.

Canvas-leather blends dominate this segment. Canvas is a breathable material and is great for foot comfort when the shoe is worn for long periods. Split leather overlays for abrasion resistance. To give the shoe structural integrity, a different bonding method is employed, which is PU cement that adheres to both porous textile and dense hide.

For outsoles, vulcanized rubber gives the canvas shoe its tough exterior that is versatile enough to handle any surface. When lifestyle shoes fail, customers do not complain. They stop buying altogether, so getting the shoe construction right is crucial.

Formal footwear is judged in silence. Creasing patterns. Edge paint quality. Stitch symmetry. This category punishes shortcuts.

Genuine leather grading matters. Full-grain hides resist surface cracking. Corrected leather hides defects but sacrifices longevity. Microfiber linings outperform pigskin in moisture management and odor control. Soles stitched with Blake or Goodyear constructions survive resoling. Cemented soles die when the glue fatigues.

Outsole compounds must withstand oil exposure from office flooring treatments. TPR blends outperform basic rubber here. Formal collections that ignore chemical exposure fail quietly, one peeling sole at a time.

Adventure shoes operate at failure thresholds. Water ingress destroys uppers. Abrasion eats rending. Stitching zones must be reinforced with bar-tacks and high-denier threads, Tex 70 or higher.

Water resistance is not membrane marketing. It is seaming sealing discipline. Hot-melt tapes applied under controlled pressure. Stitch perforations sealed internally. Deep-lug rubber soles use high silica compounds for wet traction. Heel cups molded with impact-dispersing ribs.

Outdoor footwear without ruggedization is cosplay. Customers feel betrayed when mud exposes fantasy engineering.

Children do not walk. They assault shoes, dragging their toes and twisting heels. Flexibility is achieved through low-durometer EVA, but not at the cost of torsional collapse. Non-toxic adhesives must comply with CPSIA and EN71. Reinforced toe zones require thermoplastic shields buried under fabric skins. Breathable linings reduce fungal complaints and medical returns.

Easy-wear closures are not convenience features. They are compliance tools. Shoes that parents cannot secure properly become safety hazards.

Fashion footwear is pressure architecture. Heels concentrate load into a few square centimetres. Stability is not optional.

Heel stacks require composite shanks to distribute load from calcaneus to midfoot. Lightweight fiberglass shanks outperform steel in fatigue resistance. Cushioning must be placed precisely under metatarsal heads to prevent nerve compression.

Surface treatments such as foil stamping and embroidery must survive friction. Embellishments that detach become refund triggers.

A fashionable shoe that injures its wearer becomes a public relations crisis.

In embroidered shoes thread selection matters a lot. Polyester embroidery threads outperform rayon in colorfastness and tensile retention. Stitch density must be considered, as it plays a role in shoe durability. Too sparse and motifs deform. And too dense means uppers become rigid, tending to tear apart at flex zones.

For backing materials non-woven stabilizers are utilized to prevent puckering. However, a breathable material must be used to avoid moisture trapping. Moreover, adhesive lamination must survive washing without delamination halos appearing around motifs.

Positioning of embroidery must avoid high-stress zones such as vamp flex points. Otherwise, every step becomes a micro-tear event.

Seasonal design drops attract attention. Core line durability retains revenue. The two must coexist.

Trend models use experimental materials in controlled volumes. Core SKUs rely on proven compounds with documented fatigue life. Material ROI is not purchasing price. It is lifecycle profitability measured across warranty claims, reshipments, and lost customers.

Brands that rotate everything chase novelty but haemorrhage margin. Those that protect a permanent backbone compound trust.

Low-density EVA collapses. Decorative stitching fails under shear. Synthetic uppers crack in cold climates. Color bleed stains socks. Outsoles delaminate because curing times were shortened to meet ship dates. These are not accidents. They are managerial decisions. Every shortcut compound downstream cost. Every compromised test multiplies risk.

Procurement without stress testing is gambling. Samples must endure flex rigs, abrasion drums, and hydrolysis chambers before PO release. Factories must document adhesive lot numbers. Stitch counts must be audited per size range.

MOQ planning is not finance. It is risk buffering. Smaller test runs reveal failure modes before national launches. Warranty clauses must be negotiated before production, not after complaints.

Private label brands that treat sourcing as transactional end up litigating quality in public.

A powerful shoe collection is engineered, not assembled. Durable materials do not emerge from trend boards. They emerge from fatigue tests, compound selection, bonding discipline, and biomechanical respect.

The next action is not another mood board. It is material audit. Flex testing. Abrasion verification. Stitch mapping. Build the collection like a machine that must survive abuse, not a sculpture that only survives photography.

Fashion changes so rapidly, and it is always a challenge for retailers to

READ FULLFootwear is no longer a fashion category. It is a systems problem disguis

READ FULLSilver jewelry is easy to buy because it is not expensive, and it can hel

READ FULL